Automotive Engineering Software

The automotive industry is changing. Stay ahead of the curve with automotive engineering software informed by the industry.

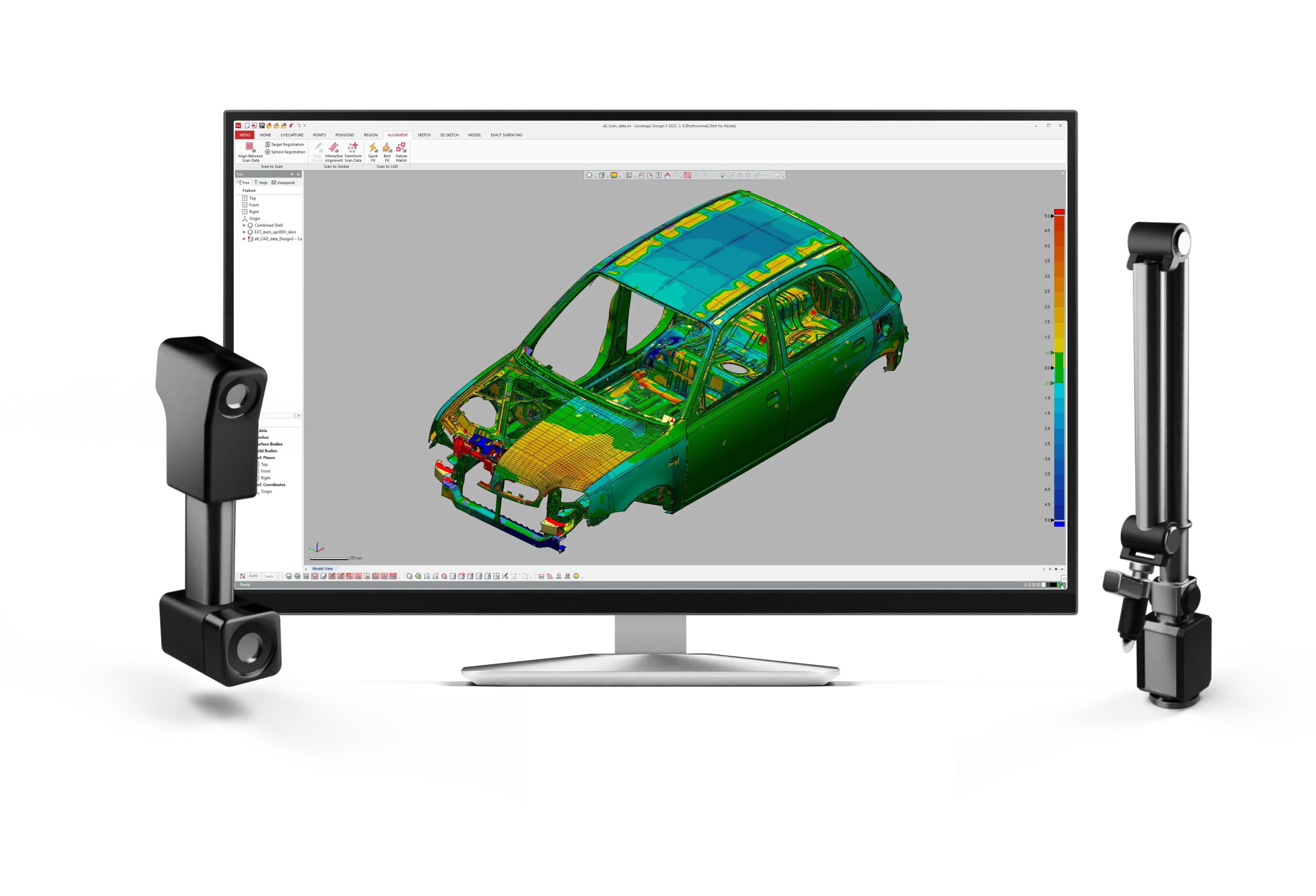

Create Smarter with Scan-Based Design

Learn how Design X modelling capabilities were used to completely retrofit a Mercedes Sprinter van conversion in this on-demand webinar.

3D scanning in the automotive industry

3D scanning in the automotive industry that enables precise measurements of complex components, allowing for improved accuracy and efficiency. Automotive manufacturers are using 3D scanning solutions for a variety of purposes, such as digitization for virtual simulation, quality control, and reverse engineering for part optimization. By leveraging 3D scanning, automotive companies can gain a better understanding of their products and how they interact with their environment.

3D scanning software for automotive industry applications include:

- Collect as-built assembly data to design replacement components that fit perfectly.

- Fast and accurate volumetric reporting, perfect for costing and planning.

- Redesign swing arms and other integral components, using existing parts as inspiration.

Additive manufacturing in the automotive industry

Additive manufacturing, or 3D printing has been revolutionizing the automotive industry by allowing for on-demand and cost-effective production of high-quality components. With advanced additive manufacturing technology, intricate and functional automotive parts, impossible with other techniques, can be produced quickly with precision and accuracy.

3D printing software for automotive industry applications include:

- Design and build automotive brackets and other components faster, stronger & lighter than other methods.

- Consolidate multiple parts into single components for reduced assembly times.

Trusted by industry partners

Hardware agnostic automotive engineering software

Automotive Industry Insights

First article inspection at Aisin China kicks into high gear with Geomagic Control X

Customer StoryApr 9, 2024Everything you need to know about 3D scanning for the automotive industry

BlogOct 4, 2023Reverse Engineer, Repair & Rebuild. 3D Scan, Reverse Engineering und 3D Druck für die Ersatzteilproduktion

On Demand WebinarJul 6, 2023What is 3D scanning? A beginner’s guide

BlogMay 25, 2023FAQ

What is automotive engineering software?

Automotive engineering software enables companies across all areas of automotive manufacture, from OEMs to aftermarket modification workshops, to digitize, design and manufacture various automotive components to empower the creation of quality vehicles.How does our automotive engineering software work?

Oqton’s automotive engineering software solutions enable you make huge process efficiency gains across your manufacturing process. Our solutions help you optimize your production process across reverse engineer, inspection, additive design, build preparation, print optimization and scheduling.Why partner with Oqton?

Oqton’s open platform and software technologies are compatible with all additive manufacturing and scanning equipment used by automotive manufacturers. Our AI-powered solutions help to increase efficiencies and reduce costs to ensure high quality production, regardless of the size of your business.Why should you use Oqton’s automotive engineering software solutions?

Oqton’s automotive engineering software solutions will help to improve your manufacturing quality, ensuring reliable part accuracy for automotive production.

Our additive manufacturing solutions enable you to create complex geometries with higher precision and accuracy than ever before, while our 3D scanning solutions allow you to capture detailed data from real-world products, to reverse engineer or inspect quickly and efficiently.

We also employ cutting-edge AI and machine learning technologies to improve the quality and accuracy of your automotive designs. Together, our solutions will help you maximize efficiency and cost-effectiveness for your automotive engineering projects.Is the software compatible with industry-standard file formats and automotive tools?

Yes, all of our products support the import and export of most industry standard file formats, enabling you to easily integrate into your existing manufacturing processes and tools.Can Oqton’s software be integrated with my existing manufacturing systems?

Yes, Oqton’s Manufacturing OS can connect directly to your existing enterprise systems such as your ERP, CRM, PLM utilizing our open API layer.How much does Oqton’s automotive engineering software cost?

We have both perpetual and subscription licensing options across our software portfolio, including maintenance plans. For more information on pricing for your region, contact us to speak to a member of the team.What automotive parts can Oqton’s engineering software help create?

Oqton’s automotive engineering software can aid in the design and manufacture of engines, transmissions, suspensions, fuel systems and much more. Whether you are trying to optimize component designs, digitize for analysis, or consolidate assemblies for lightweighting, it can enhance your design, engineering and manufacturing workflows to help you produce high quality original or aftermarket parts more efficiently.Can Oqton’s automotive engineering software solutions integrate with my existing software and hardware?

Yes, we pride ourselves on our integration with your existing software and hardware. Our additive manufacturing and 3D scanning software are both hardware agnostic, enabling you complete flexibility in your manufacturing workflows.What are the key features of Oqton’s automotive engineering software solutions?

We have a wide offering of automotive engineering software solutions across 3D scanning and additive manufacturing, tailored to address specific highly-regulated industry challenges. For more information on these, follow the links below:

- Geomagic Design X - 3D Reverse Engineering software

- Geomagic Control X - 3D Inspection and Metrology software

- 3DXpert - All-In-One Industrial Additive Manufacturing Software

- Manufacturing OS - Intelligently automate your production with a manufacturing operating system.Is the software scalable to handle projects of different sizes and complexities?

Absolutely. Oqton’s cloud-based solution can be scaled to meet the needs of organizations of any size. There are many desktop software product bundles available to scale depending on your usage. For more information, please contact us.Does Oqton automotive engineering software comply with industry standards?

Oqton’s cloud solution is SOC2 and NIST 800-171 compliant. It is also compliant with GDPR. Upon request, we are happy to provide all the necessary approvals and certifications.Can Oqton’s automotive engineering software work across different types of automotive applications, such as electric vehicle (EV) design and analysis?

Oqton’s automotive engineering software is designed to be versatile and flexible, making it perfect for many different automotive applications, including electric vehicle (EV) design and analysis. The software solutions are highly customizable, so you can tailor it to meet your specific needs. Whether you’re a startup, automotive OEM or aftermarket modification shop, Oqton can provide a comprehensive, top quality engineering solution for all your needs.